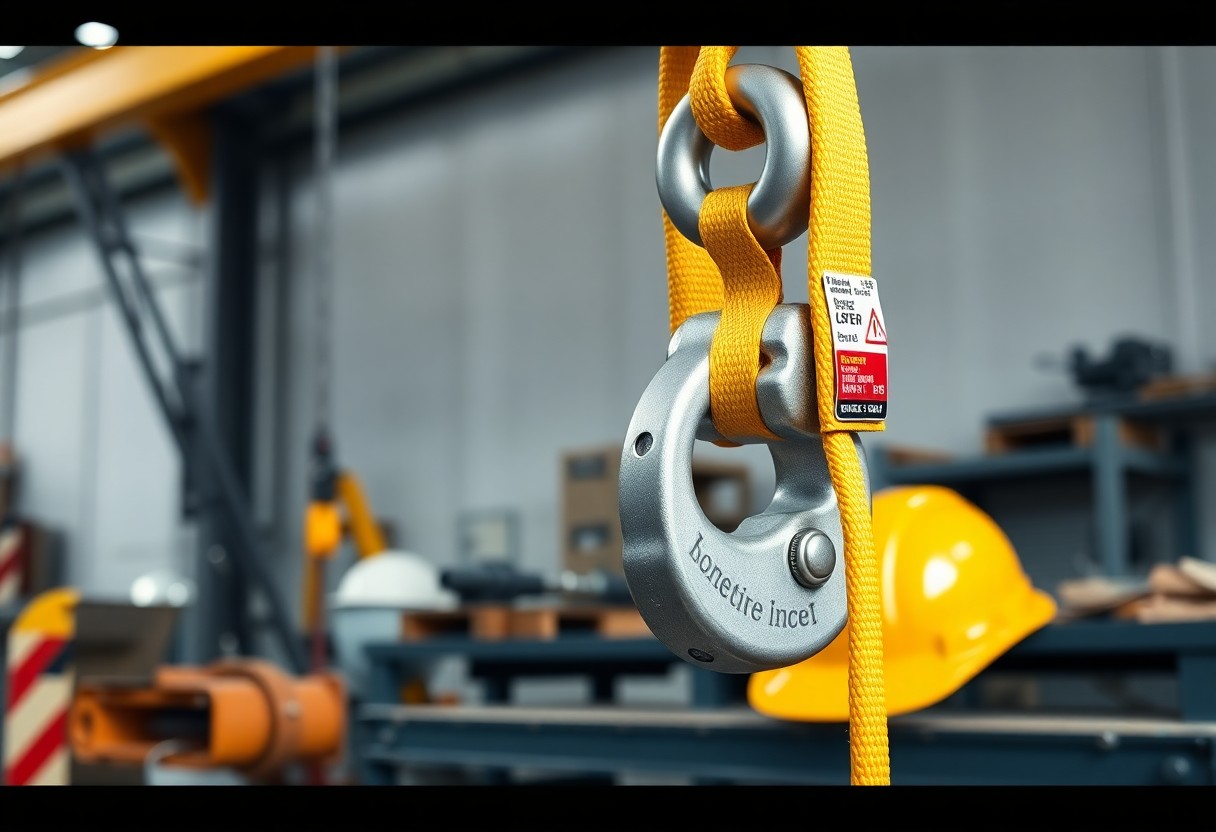

Safety begins with you inspecting slings and hooks before every lift: check for cuts, abrasion, corrosion, deformation, confirm tags and rated capacity, and never exceed load limits. Use hooks with safety latches, apply edge protection and choose the correct sling type and hitch for your load. Keep clear of suspended loads, follow manufacturer guidance, and ensure your training keeps you efficient and safe on the job.

Key Takeaways:

- Inspect slings and hooks before each use; remove and tag out gear with cuts, broken strands, heat damage, bent hooks, missing latches, or illegible ID.

- Match sling type, hitch, and angle to the lift; never exceed the Working Load Limit, avoid shock loading, protect slings from sharp edges, and keep the load balanced and centered.

- Use approved attachments and secure hooks (safety latches/spools), avoid knots, use taglines for control, follow standard hand/signaling procedures, and store/maintain gear per manufacturer guidelines.

Understanding Rigging Safety

When setting up lifts you must combine proper equipment selection, accurate load calculation and rigorous inspection. Follow manufacturer ratings and standards such as ASME B30.9 and OSHA guidance, confirm tag-rated capacity, and compute sling angles so tension stays within limits. Inspect slings, hooks, and hardware before each use, verify hitch type for the load, and account for environmental effects like heat, chemicals or abrasion that accelerate failure.

Importance of Rigging Safety

Protecting personnel and assets depends on disciplined rigging practices. By inspecting slings before use and scheduling formal checks monthly, you reduce dropped-load incidents and costly downtime. Proper selection and hitching also speed lifts-saving repositioning time-and prevent equipment damage. Implement training, documented inspections, and strict adherence to rated capacities to keep operations efficient and incident-free.

Common Hazards in Rigging

Typical hazards you’ll encounter include worn or frayed slings, side-loading hooks, shock loading, incorrect hitch selection, damaged shackles, and missing or illegible tags. Environmental exposure to heat, chemicals and abrasion accelerates degradation. Unbalanced or unsecured loads and failing to account for angle-induced tension increases further raise the risk of sudden failure.

For example, a 30° sling angle can significantly increase tension compared with a vertical lift, so keep sling angles above about 45° when possible and never tie knots in synthetic slings. Use protective sleeves on sharp edges, replace slings with missing tags, and substitute properly rated shackles for side-loaded hooks. Train your team to spot stretch, distortion and corrosion to prevent failures before they occur.

Types of Lifting Slings

You must distinguish slings by material, construction and application: synthetic web and round slings protect finishes, wire rope resists abrasion and heat, and chain handles high-temperature, sharp-edged loads. Varying elements like eye terminations, fittings and rated capacities determine safe use, and you should follow tag ratings and inspection records. Any selection must match the load’s rated WLL, sling angle, and service conditions to prevent failure.

- Synthetic

- Wire rope

- Chain

- Round

- Endless

| Synthetic web | Lightweight, non-conductive; inspect for cuts, abrasion, chemical/UV damage |

| Round slings | Continuous textile core with jacket; good for delicate finishes, protect against sharp edges |

| Wire rope | Abrasion and heat resistant; flexible choices (6×19 vs 6×37); watch for broken wires, kinks, corrosion |

| Chain | High strength, durable at elevated temperatures; use correct grade and fittings |

| Endless/eye slings | Simple geometry for baskets and chokers; ensure correct angle and tag-rated WLL |

Synthetic Slings

You should prefer nylon or polyester slings when load protection and light weight matter; nylon stretches more, polyester resists moisture and UV better. Inspect daily for cuts, snags or chemical attack and remove from service if the jacket is abraded or the core exposed. Manufacturers often apply safety factors between 5:1 and 7:1, and you must never exceed the stamped WLL or use them above their temperature/chemical limits.

Wire Rope Slings

You will choose wire rope for abrasive, hot or high-cycle lifts; common constructions are 6×19 (better crush resistance) and 6×37 (more flexible). Inspect for kinks, birdcaging, corrosion and broken wires; per OSHA guidelines remove if there are six broken wires in one rope lay or three broken wires in one strand in one lay. Always confirm WLL by diameter and construction and tag the sling accordingly.

For more depth, you should focus on end terminations (thimbles, swaged sockets, poured sockets, mechanical clamps), lubrication and re-splicing practices: properly installed swages and sockets retain rated strength, but heat damage, crushing, or improper fittings can reduce capacity dramatically. You must avoid shock loading, never untwist or re-use kinked rope, and schedule periodic load testing and professional re-certification when repairs are made.

Safety Standards and Regulations

OSHA Guidelines

Per OSHA (29 CFR 1910.184 and 1926.251) you must use slings and hooks marked with their rated capacity (WLL), inspect them before each shift, and remove any with cuts, severe abrasion, or deformation. You should follow prescribed attachment methods, ensure hooks have required latches where specified, and keep documentation for inspections to avoid citations and fines for overloading or improper rigging.

ANSI Standards

ANSI/ASME B30 series (notably B30.9 for slings, B30.10 for hooks, B30.26 for rigging hardware) requires manufacturer identification, proof testing, and published tables for capacities; design factors typically range from 4:1 to 5:1 depending on material. You must follow ANSI load-rating tables, marking rules, and inspection intervals to maintain traceability and safe service life.

Digging deeper, ANSI mandates angle factors and reduction tables you must apply: for example, a sling angle that deviates from vertical can reduce leg capacity by roughly 30% at 45°, so you need to recalculate WLL per leg using the ANSI tables. You should also keep records of manufacturer proof tests and repair history to validate continued use after any damage or rework.

Proper Use of Lifting Hooks

You must seat the load in the hook throat, keep the load capacity label visible, and always use a safety latch on overhead lifts; never side-load hooks designed for straight pulls. Match sling angles-e.g., a 60° sling angle almost doubles tension versus vertical-and avoid shock loading. Inspect for deformation, cracks, corrosion, or elongation before each lift and tag out any suspect hook immediately.

Types of Hooks and Their Uses

You should choose eye hooks for stable single-point lifts, clevis hooks when connecting to chain, and swivel hooks when rotation is expected; many hooks are rated from 1t to 20t. Use grab hooks to shorten chain but avoid them with synthetic slings, and prefer self-locking hooks for critical overhead lifts. Perceiving how each hook concentrates load will help you prevent bending, overload, and accidental detachment.

- Eye Hook – single-point, stable lifts.

- Clevis Hook – chain connections, accepts clevis pin.

- Swivel Hook – allows rotation, reduces twist.

- Grab Hook – shortens chain, not for slings.

- Self-Locking Hook – automatic latch for overhead work.

| Eye Hook | Stable single-point lifts; common ratings 1t-10t |

| Clevis Hook | Chain systems; used with clevis pins and tensioners |

| Swivel Hook | Rotating loads; prevents sling twist, 2t-15t typical |

| Grab Hook | Adjusts chain length; not for wire rope or webbing |

| Self-Locking Hook | Critical overhead lifts; latch secures under load |

Inspection and Maintenance

You must inspect hooks before each shift and after any abnormal event, checking for cracks, excessive wear, corrosion pitting, bent points, or illegible capacity markings; remove any hook with visible fracture or deformation and tag it out. A practical threshold is to retire hooks showing more than ~10% elongation or severe throat opening increase compared to original dimensions.

For maintenance, you should measure key dimensions with calipers, perform dye-penetrant or magnetic-particle tests for suspected cracks, lubricate swivels per manufacturer specs, and log inspections in your equipment register; schedule detailed inspections monthly and a certified inspection annually. Training your crew to detect weld repairs, nicks, and unauthorized modifications reduces accidents and ensures compliance with load-rating requirements.

Rigging Equipment Inspection

You must inspect slings, hooks and attachments before every use and schedule formal checks at least monthly for daily-use gear; log findings with date and inspector. Prioritize visible damage, load-rating legibility and certification tags, and remove items showing deformation or heat damage. For more procedural guidance consult Safety Tips for Safe Lifting.

Regular Inspection Protocols

Your pre-use walkaround should verify ID tags, rated capacity, and general condition, while formal inspections include full-length rope checks, sling-angle capacity verification, and documented measurements. Perform formal inspections monthly for daily-use gear and quarterly for occasional equipment; keep records for at least one year. If a hook’s throat opening increases by more than 15% or you see twisting or nicks, remove the hook from service immediately.

Identifying Defects

You need to spot frayed fibers, broken wires, heat discoloration, chemical etching, kinks, pitting, elongation, and illegible markings. Pay special attention to synthetic slings with melted or fused fibers and wire rope with visible broken wires or severe corrosion. Any sling with missing ID tags or suspected internal core damage must be tagged out and isolated until evaluated by a qualified inspector.

Inspect methods matter: use bright light and flex synthetic slings to reveal hidden cuts, unlay wire rope to check for internal broken wires, and measure hook throat with calipers against original specs. Photograph defects and record exact locations and measurements to support trend analysis and investigations. If you find damage, do not attempt field repairs-follow the manufacturer’s reconditioning procedures or send components to a certified repair facility.

Safe Lifting Practices

You must verify the sling’s rated capacity against the known load weight and center of gravity before each lift, inspect for cuts, broken stitching, and bent hooks, and ensure rigging hardware is properly seated. Conduct a quick pre-lift check (2-5 minutes) to confirm hitch type, load balance and clearances, keep personnel at least 3 m (10 ft) away, and avoid shock loading by lifting smoothly and controlling swing with taglines.

Techniques for Safe Lifting

Use hitch selection to your advantage: a basket hitch roughly doubles sling capacity while a choker reduces it; never accept sling angles below 45°-angles near 30° can almost double tension. Employ spreader bars or lifting beams to maintain rigging geometry, protect edges with softeners, and attach taglines to control rotation; practice planned, slow pick-ups to detect imbalance before committing to travel.

The Role of Communication in Rigging

You must assign a designated signal person and use standardized hand signals or two‑way radios with repeat-back confirmation. Hold a concise 2-5 minute briefing covering load weight, sling configuration, travel path and hazards, then confirm the emergency stop word and contingency plan so everyone knows when to halt the lift immediately.

For added clarity, document the lift plan and post it where crew can see it: include measured weight, center of gravity, sling types, and angles, plus the name of the signal person and radio channel. Use a single, unambiguous emergency stop word, rehearse critical maneuvers, and log any deviations after the lift to prevent repeat errors.

Final Words

From above, you must inspect slings and hooks before each lift, follow rated capacities and angle limits, secure attachments, and use taglines to control loads; if any damage or deformation appears you stop the operation and report it, and you maintain clear communication with your crew to ensure safe, controlled lifts.

FAQ

Q: How should I inspect lifting slings and hooks before use?

A: Perform a visual and tactile inspection before each use and a formal inspection at regular intervals per manufacturer and site rules. For slings check for cuts, frays, broken wires, melted or burned areas, acid or chemical damage, excessive wear, elongation, crushed or deformed fittings, missing or unreadable ID tags. For wire rope look for core damage, birdcaging, kinking and corrosion. For hooks inspect for cracks, excessive throat opening or bend, worn bearing surfaces, corrosion, and functional safety latches. Remove any damaged sling or hook from service, tag it out, and have it evaluated by a qualified person before reuse.

Q: How do I select the correct sling type, size and rigging configuration for a lift?

A: Determine the lifted weight, center of gravity, load dimensions and any sharp edges or temperature/chemical exposures. Choose a sling material and type (wire rope, chain, synthetic web, endless, or mesh) suited to the load environment and endpoint attachments. Use slings with adequate rated capacity (WLL) and intact ID tags. Select hitch type-vertical, choker or basket-based on stability and capacity needs and apply angle factors: as the sling angle from vertical increases (becomes more horizontal) tension in each leg rises, so consult manufacturer angle tables or compute load per leg = (total load / number of legs) / cos θ (θ = angle from vertical). Use edge protection where required, avoid knots in slings, and ensure all hardware (shackles, hooks, master links) is rated and compatible.

Q: What safe practices should be followed when using hooks and attaching loads?

A: Seat the load properly in the hook bowl so the load bears on the hook body, not the tip; never tip-load or side-load a hook unless it is designed for that use. Ensure safety latches are installed and functional when required. Match hook size and capacity to the sling and load; use appropriate fastenings (shackles, couplers) and secure connections. Control the load with taglines; keep personnel clear of suspended loads and do not allow anyone to ride a load. Avoid shock loading, sudden stops or starts, and dragging slings across abrasive or sharp surfaces. After use store slings and hooks clean, dry and protected from sunlight, chemicals and corrosive environments to prolong service life.