Safety requires you to inspect for leaks, secure cylinders upright, use rated regulators, wear PPE, and keep ignition sources away to prevent explosions.

Key Takeaways:

- Store and handle cylinders upright with valve protection caps in place; secure cylinders to prevent tipping and keep them away from heat sources and combustible materials.

- Use properly labeled cylinders and matching regulators; verify gas identity before use, perform leak checks with soapy water or an approved detector, and never interchange regulators between different gases.

- Transport cylinders on suitable carts with valve caps installed, never roll or drag cylinders, and follow emergency procedures for leaks or fires including safe shutoff when possible and immediate notification of emergency responders.

Hazard Identification and Classification

Hazard identification requires you to assess cylinder contents, labels, and storage to classify risks by type and severity; prioritize leak, pressure, and flammability threats and apply controls immediately.

Physical Hazards: High Pressure and Temperature

Pressure in cylinders exposes you to high-pressure release and ruptures; store upright, secure with chains, and avoid heat sources to prevent temperature-induced failures and projectile hazards.

Hazard and Controls

| Hazard | Key Controls |

|---|---|

| High pressure | Secure cylinders, inspect valves, use regulators |

| Flammable gases | Ventilation, ignition control, leak detection |

| Toxic / asphyxiant gases | Gas monitors, PPE, signage, confined-space procedures |

Chemical Hazards: Flammability, Toxicity, and Asphyxiation

Flammability and toxicity risks mean you must control ignition sources, monitor for leaks, and use proper ventilation; recognize that asphyxiant gases can displace oxygen and cause rapid unconsciousness.

Gases vary widely: you must treat flammable gases as explosion hazards with grounding and elimination of ignition, manage toxic gases with continuous detectors, clear emergency procedures, and appropriate respirators, and treat inert gases as silent oxygen-displacers requiring oxygen monitoring and confined-space controls so you can respond fast to life-threatening leaks.

Proper Storage Requirements

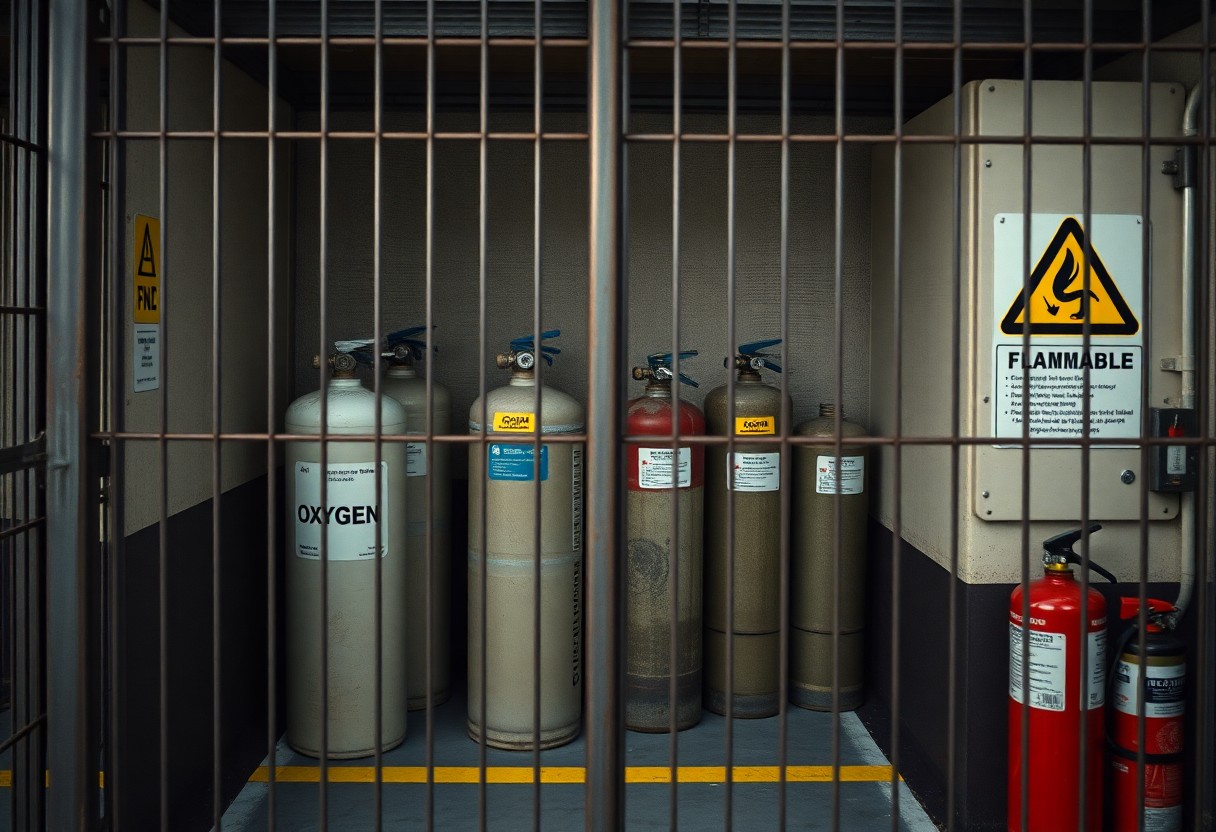

Store cylinders upright and chained to a fixed support, with valve caps on and labels visible; keep them away from heat and ignition sources. You must keep high-pressure and corrosive gases in appropriate cabinets and ensure empty cylinders are segregated from full.

Segregation and Distance Protocols

Separate cylinders by hazard class: keep flammables away from oxidizers by 20 feet or use a 5-foot, 2-hour fire-resistant barrier; you must label and store incompatible gases apart to prevent contact and accidental reactions.

Ventilation and Environmental Controls

Provide mechanical ventilation with exhaust at low points for heavier-than-air gases; you should avoid enclosed rooms and maintain continuous airflow to prevent gas accumulation.

Maintain continuous mechanical ventilation sized to prevent pockets of gas, with exhaust at the floor for heavier-than-air gases and high-level intake for light gases; you should install fixed gas detectors, link alarms to ventilation controls, and keep storage areas temperature-controlled and free of ignition sources to reduce risk of asphyxiation or explosion.

Safe Handling and Transportation

Handle cylinders carefully when you move them; keep valves capped, protect from impact, transport upright, and consult SAFETY MEETING TOPIC: Compressed Gas Safety for practical steps.

Securing Cylinders for Transit

Secure cylinders in transit with chains or racks so they can’t tip or roll; ensure valves are protected and labels remain visible during transport.

Use of Carts and Proper Lifting Techniques

Employ approved cylinder carts when you move bottles, strap cylinders securely, and position heavier cylinders closest to the cart base to reduce tipping.

When you must lift cylinders, ask another person for heavy loads, keep the cylinder vertical, bend at the knees rather than the waist, avoid twisting, push carts instead of pulling, and use mechanical hoists or team lifts for oversized cylinders to reduce strain and impact hazards.

Inspection and Maintenance Procedures

Inspect cylinders and storage areas regularly using your checklist for dents, corrosion, missing tags, or damaged valves; tag out leaking or compromised units and remove them from service until certified.

Pre-Use Visual Checks and Leak Testing

Before each use you must visually inspect connections, hoses, and cylinders for cracks, oil, or frost; perform a soapy water leak test and never use a cylinder that shows persistent bubbles or smell of gas.

Regulator and Valve Integrity Standards

Verify regulator dates, serial numbers, and pressure ratings match cylinder contents; you must check threads and handwheels for damage and ensure valve seats seal fully before pressurizing.

Perform regulator bench tests and replace diaphragms per manufacturer intervals; avoid oil or grease on oxygen fittings, use correct torque, and ensure you have damaged regulators repaired by qualified technicians to prevent high-pressure failures.

Emergency Response Procedures

When an incident occurs, you must isolate the area, shut cylinder valves if safe, and activate alarms. Assign roles to trained responders, contact emergency services, and follow your site’s incident plan to reduce exposure and prevent escalation.

Managing Accidental Releases and Leaks

If you detect a leak, immediately evacuate nonnecessary personnel, ventilate the space only if safe, and shut cylinder valves using remote or PPE-protected methods. Notify supervisors and emergency responders, and prevent ignition sources near flammable gases.

Fire Safety and Evacuation Protocols

During a fire threat, you must evacuate immediately, keep clear paths to exits, and move upwind from cylinders. Trained responders should shut off gas supplies only if conditions allow; never fight pressurized-gas fires without specialized equipment.

Follow preplanned routes, assemble at designated muster points, account for personnel, deploy extinguishers only for small, contained flames if trained, and keep emergency responders informed; do not re-enter until the scene is declared safe.

To wrap up

Taking this into account, you must store and transport compressed gas cylinders upright and secured, inspect valves and regulators before use, use correct regulators and PPE, keep cylinders away from heat and ignition sources, and follow emergency procedures to protect people and property.

FAQ

Q: What are the basic safe handling procedures when working with compressed gas cylinders?

A: Inspect the cylinder, valve, regulator, and label before use for signs of damage, corrosion, oil/grease contamination, or incorrect gas identification. Keep cylinders upright and secured with chains or straps during use and storage; use regulator and fittings rated for the specific gas and pressure. Use valve protection caps when moving cylinders and transport them with an appropriate cart; never roll, drag, or lift by the valve. Open cylinder valves slowly, standing to the side of the outlet, and use only approved leak-detection solutions (no open flames). Close valves and replace protective caps when equipment is not in use. Wear required PPE such as safety glasses, face shields, gloves, and respiratory protection if specified by the gas SDS or site procedures.

Q: How should compressed gas cylinders be stored and segregated?

A: Store cylinders in a well-ventilated, dry, and cool area away from heat, direct sunlight, and ignition sources. Segregate oxidizers and oxygen cylinders from flammable and combustible gases by at least 20 feet or by a noncombustible barrier at least 5 feet high with a 30-minute fire-resistance rating. Clearly mark areas for full and empty cylinders and return empty cylinders to storage with valves closed and caps installed. Secure cylinders upright and prevent contact with electrical circuits or sharp objects. Prohibit storage near corrosive chemicals that could attack cylinder metal or labels. Post signage identifying hazards and access restrictions.

Q: What actions should workers take during a leak, fire, or other emergency involving compressed gas cylinders?

A: Evacuate nonimportant personnel and isolate the area; eliminate ignition sources for flammable gases if it can be done safely from a distance. If trained and it can be performed without risk, shut off the cylinder valve; do not attempt if the leak or fire is large or the cylinder is too hot. For toxic or asphyxiating gases, use appropriate respiratory protection or wait for emergency responders with SCBA. For cylinders exposed to fire, apply cooling water spray from a safe distance to prevent pressure build-up and notify the fire department; do not extinguish a surrounding fire if a high-pressure cylinder is involved without professional guidance. Report the incident to supervisors, follow the facility emergency plan, and preserve incident details for investigation.