Over 2,000 workplace eye injuries occur yearly; you must wear ANSI-certified eyewear and face shields when exposed to flying debris, chemicals, or heat to prevent permanent vision loss and facial trauma.

Key Takeaways:

- Proper eye and face protection matches the hazard: safety glasses with side shields for impact, chemical splash goggles for liquid exposure, and full face shields for grinding or high-velocity operations.

- Inspect protective equipment before each use; replace scratched, cracked, or warped lenses and follow manufacturer cleaning and care instructions to maintain visibility and protection.

- Employers provide training, perform hazard assessments to specify required protection, and ensure workers have correctly fitted or prescription safety eyewear when needed.

Identifying Workplace Eye and Face Hazards

Identify the tasks where impact, flying debris, chemical splash, intense heat, or radiation can reach your eyes or face. You must assess tools, processes, and PPE gaps so you can pick the right protection for each hazard and task.

Impact, Dust, and Flying Debris

Wear impact-rated safety glasses or face shields when tools, grinders, or conveyors create flying debris and dust that can abrade or penetrate your eyes.

Chemical, Heat, and Radiation Exposure

Shield your face with chemical splash goggles or full-face respirators whenever acids, solvents, hot liquids, or welding radiation could cause burns or blindness.

Select PPE that matches the hazard: sealed chemical goggles for splashes, face shields plus goggles for high-velocity liquids, welding helmets with the correct shade for UV/IR, and heat-resistant shields for molten metal. Inspect seals, lenses, and straps before each use, store and clean equipment properly, and confirm compatibility with respirators to reduce risk of chemical burns, thermal injury, or permanent vision loss.

Selection of Appropriate Personal Protective Equipment (PPE)

You must match PPE to the specific hazard, selecting eye and face protection rated for impact, chemical splash, or welding radiation; ensure proper fit, inspection, and training so your protection performs when needed.

Safety Glasses and Prescription Requirements

Choose safety glasses that meet ANSI/OSHA standards and fit snugly over or with prescription lenses; opt for impact-rated frames and side protection when tasks create flying debris.

Goggles, Face Shields, and Welding Helmets

Wear goggles for chemical and dust hazards, face shields for splash and thermal exposure, and welding helmets for arc and UV protection; always pair shields with impact-rated eyewear when direct strikes or fragments are possible.

Inspect goggles and helmets before each shift, checking seals, lens coatings, and auto-darkening functions; replace scratched or damaged lenses because reduced visibility and compromised protection increase your risk of serious eye injury.

Proper Use and Fitment Standards

Follow manufacturer guidelines for cleaning, inspection, and replacement so you maintain protective performance; a proper fit and undamaged lenses reduce impact and chemical splash risks and ensure compliance with standards.

Ensuring Secure and Comfortable Fit

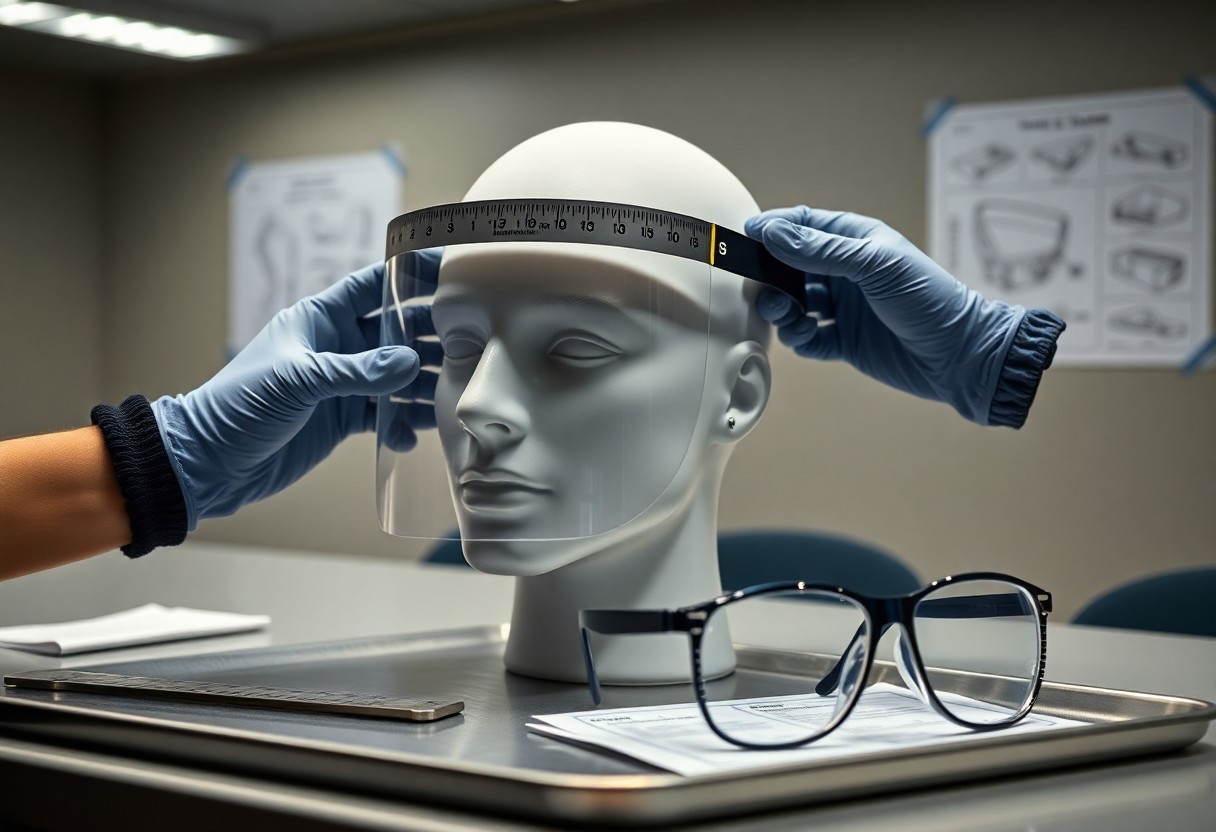

Check that the frame sits snugly without pressure points, straps are adjusted, and gaps around the temples and nose are minimized so you balance comfort with secure protection and avoid accidental exposure.

Integration with Other Safety Equipment

Adjust headgear, respirators, and helmets so your eye protection nests correctly; you ensure seals, face shield overlap, and visor alignment to prevent blind spots and leakage.

Coordinate adjustments with coworkers when using multiple devices so you preserve respirator facepiece seals and helmet stability; mismatched gear can create gaps that allow toxic splashes, flying debris, or heat exposure, and you should verify prescription inserts and side shields for compatibility and clear field-of-view.

Emergency Response for Ocular Injuries

Act fast after an eye injury: stop exposure, remove contact lenses if you can, avoid rubbing, and call for help; for chemical splashes or embedded objects follow emergency protocols immediately.

Immediate First Aid Protocols

If you face a chemical splash, flush the eye for at least 15 minutes with clean water; for cuts or foreign bodies, cover the eye and seek medical care. Keep pressure off the eye and avoid ointments. Flush continuously and call emergency services for serious injuries.

Operation of Emergency Eyewash Stations

Use the eyewash by holding eyelids open, positioning your eyes in the stream, and rinsing for a minimum of 15 minutes; remove contacts during flushing. Activate the unit before entering if splashed. Continuous flushing reduces chemical damage-keep rinsing until medical help arrives.

Maintain your eyewash readiness by testing weekly, keeping water clear and tepid, and ensuring unobstructed access within ten seconds of hazard areas. You must train staff on activation, flow rate, and head positioning, and document inspections so faults are fixed before a chemical emergency occurs.

Regulatory Standards and Compliance

Regulatory oversight means you must follow federal and industry standards for eye and face protection; OSHA and ANSI set rules for selection, use, and training. Keep approved PPE in service and documentation current to cut eye injury risk and avoid citations.

Understanding ANSI Z87.1 Markings

ANSI Z87.1 markings show you whether eyewear meets impact, splash, or welding standards; read lens and frame codes to confirm impact-rated lenses, side protection, or UV filtering before use.

OSHA Requirements for Workplace Safety

OSHA requires you to perform hazard assessments, supply appropriate eye and face PPE, and train employees on use and care; maintain records and enforce use to prevent serious eye injuries and citations.

You must document a written PPE program that specifies hazard assessments, selection criteria, and training schedules; ensure prescription and nonprescription eyewear comply with ANSI Z87.1, verify fit and condition each shift, replace scratched or damaged lenses promptly, and keep training and inspection records. Violating these steps increases risk of serious eye injuries and exposes you to OSHA citations.

Final Words

With this in mind you must wear and enforce ANSI-rated eye and face protection, inspect and replace damaged gear, and train your team to recognize hazards to reduce injuries and maintain a safe workplace.

FAQ

Q: What types of eye and face protection should workers use for specific hazards?

A: Match protection to the hazard: safety glasses with side shields for impact hazards, chemical splash goggles for liquid hazards, and full face shields over goggles for high‑energy splashes or molten metal. Use welding helmets with the correct shade lens for radiant energy and specialized goggles or shields for grinding and cutting. Choose polycarbonate or other impact‑resistant lenses rated to ANSI/ISEA Z87.1 standards, and select anti‑fog, UV‑blocking, or scratch‑resistant coatings as needed. Inspect PPE before each use for cracks, deep scratches, loose frames, or degraded straps and replace immediately if damaged. Clean and store gear in protective cases away from heat and chemicals to preserve optical quality and fit.

Q: How do you conduct an effective safety talk on eye and face protection?

A: Start the talk by describing common task‑specific hazards and any recent incidents to make the message relevant. Demonstrate correct selection, donning, adjustment, inspection, cleaning, and storage of each type of protection used on site. Provide hands‑on fitting practice and verify understanding with short quizzes or return demonstrations. Explain the site PPE policy, reporting procedures for damaged gear, and the schedule for refresher training. Document attendance and issue job‑specific reminders or pocket guides to reinforce safe behavior after the talk.

Q: What common mistakes reduce the effectiveness of eye and face protection and how can they be prevented?

A: Common mistakes include using the wrong category of PPE (safety glasses instead of goggles for chemical splash), wearing scratched or warped lenses, poor fit that leaves gaps, relying on regular eyeglasses instead of rated protection, and removing protection to communicate. Prevent these errors by conducting hazard assessments, providing the correct PPE types and sizes, enforcing a pre‑use inspection routine, and replacing damaged equipment promptly. Train workers on correct use and storage, assign supervisors to model and enforce compliance, and track PPE issuance and maintenance through simple logs or checklists.